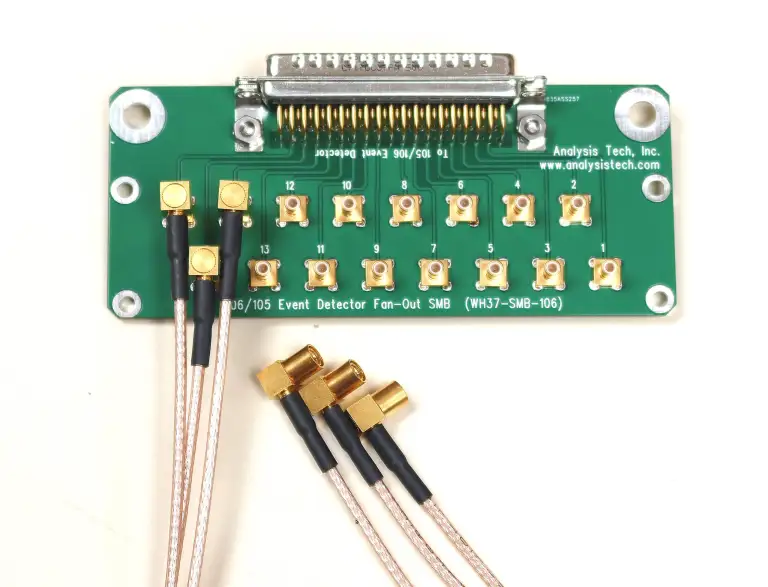

SMB Selection

Selecting the right SMB connector is crucial for ensuring signal stability and system performance in high-frequency applications. Known for its compact design and excellent RF performance, SMB connectors are widely used in communication, medical, and test equipment. This guide covers the key factors, application scenarios, and practical tips to help you make informed decisions when choosing SMB connectors.

SMB Characteristics

Compact Design

SMB connectors feature a small footprint, making them ideal for space-constrained applications such as wireless communication modules and portable test devices.

Ease of Use

The push-fit interface allows for quick and easy connection and disconnection, suitable for applications requiring frequent insertion and removal.

High-Frequency Performance

Supporting frequencies up to 4 GHz, SMB connectors meet the demands of most medium to high-frequency applications, ensuring reliable signal transmission.

Key Factors for SMB Connectors

Frequency Range

Ensure the SMB connector supports your application’s required frequency. For applications near the 4 GHz limit, consider optimized high-performance options.

Insertion and Return Loss

Lower insertion loss minimizes signal degradation, while higher return loss indicates better impedance matching, both critical for high-frequency performance.

Material and Environmental Suitability

Choose materials with resistance to corrosion, high temperature, or moisture as needed. Gold-plated contacts improve durability and conductivity.

Mechanical Performance

In vibration-prone environments, select connectors with robust mechanical structures to prevent contact failure and enhance system reliability.

Typical Applications of SMB Connectors

Communication Equipment: Wireless routers, RF antennas

Medical Electronics: ECG machines, ultrasound devices

Automotive Electronics: In-car navigation, communication modules

Test Instruments: High-frequency testing equipment

Tips for Selection and Maintenance

Collaborate with Suppliers

Provide detailed technical requirements, including frequency range, environmental conditions, and size constraints, to ensure optimal product selection.

Regular Inspection and Maintenance

Clean connector contacts regularly and check for wear or damage. Replace components as needed to maintain performance.

Proper Storage

Store unused connectors in a dry environment and use dust caps to protect the contacts.